En cette fin d’année 2021, pourquoi ne pas prendre la résolution de vous procurer un sac écologique, personnalisé et coloré ? Ce sac cabas constituera une véritable alternative au sac plastique pour faire vos courses et transporter vos affaires. Peu coûteux, réutilisable et plus esthétique que le plastique, le cabas écologique, coloré et personnalisé des Mouettes Vertes vous permettra d’allier engagement citoyen et style…

Voilà une résolution en théorie assez facile à tenir. Chez Les Mouettes Vertes, c’est même de cette simple idée que sont nées notre démarche et notre entreprise : proposer des sacs cabas personnalisés, pratiques, résistants et écologiques pour faciliter votre quotidien tout en protégeant la planète.

Mais c’est là que les ennuis commencent. Comment mesurer l’impact écologique d’un sac de courses par rapport à un autre ? Est-ce vraiment faire un geste responsable que d’acheter ce cabas réutilisable personnalisé en polyester ? Comment justifier le prix plus élevé de cet autre cabas en coton, coloré, personnalisé pour un usage strictement identique ? Est-il vraiment nécessaire d’entamer une telle démarche, alors même que certains sacs plastiques sont présentés comme recyclables, voire compostables ?

Pas de panique : nous tenterons dans cet article de vous éclairer sur les options qui s’offrent à vous, en faisant un tour d’horizon des sacs écologiques personnalisés disponibles sur le marché et en repérant ceux qui ont un véritable impact sur votre façon de consommer.

Premier constat : trop de plastique

Les sacs plastiques traditionnels

Les plastiques conventionnels

Grande innovation industrielle du siècle dernier, le plastique apparaît, sous de multiples formes, de manière récurrente dans la vie quotidienne. Sa polyvalence en a fait un matériau incontournable de conditionnement, depuis les produits de beauté jusqu’à l’alimentation, en passant par les meubles, les transports, et même nos vêtements et bijoux. Les avantages liés à son utilisation cachent de nombreux défauts sur le long-terme. Si le plastique s’avère très utile notamment en tant qu’emballage ou contenant ; en revanche, son recyclage reste difficile à mettre en œuvre et constitue un véritable enjeu environnemental et sanitaire.

La stabilité des matières plastiques, garante de leur efficacité lorsqu’il s’agit par exemple de la conservation des aliments dans des contenants étanches, constitue un des aspects du problème. Lent à se dégrader, le plastique subsiste en effet jusqu’à plusieurs centaines d’années dans sa forme originelle et représente un véritable danger pour les écosystèmes dans lesquels il est rejeté. C’est par exemple le cas pour les milieux marins, qui recueillent chaque année jusqu’à 8 millions de tonnes de plastique non traité. Sacs plastiques, cotons tiges, bouteilles d’eau et autres déchets sont ainsi ingérés par la faune marine, contribuant à décimer certains de ses représentants les plus rares : tortues ou oiseaux marins prennent ainsi souvent les déchets plastiques pour des proies, et meurent intoxiqués ou étouffés.

Par ailleurs, la dégradation du plastique, quand elle finit par survenir, n’améliore en aucun cas la situation. En effet, le plastique a la particularité de ne pas être assimilable par des micro-organismes, mais de se déliter en particules de plus en plus fines. Ingérées par la faune et notamment les poissons dont l’homme est friand, ces particules pénètrent ainsi dans la chaîne alimentaire et se logent dans nos propres tissus. Toxiques à forte dose, et rattachées à la longue liste des perturbateurs endocriniens, elles nuisent ainsi à notre santé comme à celle des autres espèces.

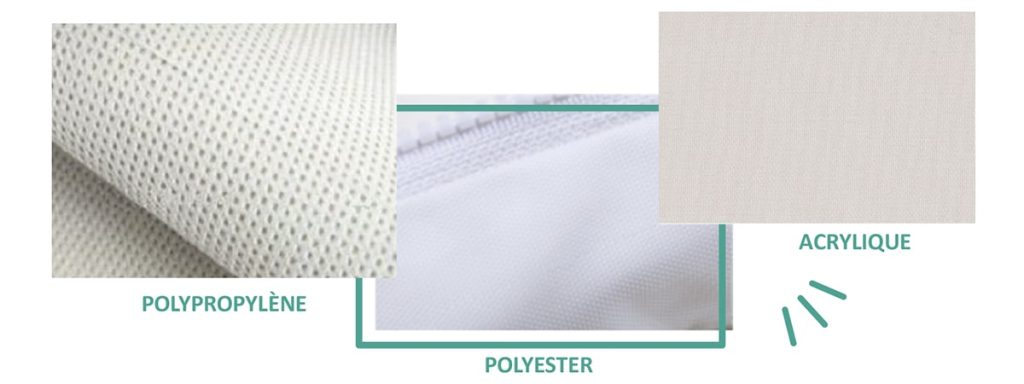

À ce titre, réduire notre consommation de plastique paraît essentiel et demande une plus grande vigilance de notre part : le plastique n’est en effet pas repérable immédiatement dans tous ses usages. La présence de microbilles de plastique est par exemple monnaie courante dans certains produits cosmétiques, comme les gommages pour la peau, et on retrouve le plastique sous des formes dérivées dans de nombreux gels douche ou dentifrices : c’est en effet lui qui assure l’onctuosité de ces produits. En ce qui concerne le textile, les fibres synthétiques comme le polyester et ses dérivés ou encore l’acrylique sont des formes de plastique, et si elles ont l’avantage de la résistance et de la souplesse, en revanche elles ne constituent en aucun cas une solution durable dès lors qu’elles sont utilisées dans le cadre de la fast fashion : les vêtements sont en effet jetés avant même d’être usés. Enfin, leur recyclage est coûteux et encore peu pratiqué, surtout dans le cas de textiles composés à la fois de fibres synthétiques et naturelles, qu’il faudrait séparer afin de les traiter différemment.

Dans cette perspective, l’achat d’un cabas en polyester, en polypropylène (matière utilisée par la majorité des marques de luxe accessible, qui rappelle un peu la feutrine) ou en acrylique n’est pas une véritable alternative écologique. De plus, l’immense majorité de ces modèles de cabas sont colorés grâce à des bains de teintures non naturelles et participent en plus à la pollution des sols et des eaux. Mieux vaut donc s’orienter vers des cabas et fibres naturelles, à condition qu’ils aient obtenus les labels prouvant leur innocuité pour l’environnement et la santé.

Le cas des bioplastiques

Pour pallier les difficultés liées aux plastiques conventionnels, ont été développées de nouvelles formes de plastique dites « biosourcées » ou « biodégradables », censées atténuer l’impact environnemental des sacs et emballages employés dans la grande distribution. À ce titre, est-il vraiment nécessaire de se tourner vers les fibres naturelles, et d’interdire le plastique à usage unique ?

En réalité, ces produits ne constituent pas une alternative viable en matière d’éco-responsabilité. En effet, derrière les appellations alléchantes citées plus haut, se cachent des matériaux dont le caractère naturel ou biodégradable reste très limité, et qui introduisent même de nouveaux biais de complexité dans le traitement des plastiques en fin de vie. À noter notamment que le terme « biodégradable » n’a fait l’objet d’aucune réglementation stricte pour les produits autres que les emballages : il peut donc tout à fait être utilisé de manière abusive par les producteurs de matériaux plastiques adeptes du greenwashing.

Les plastiques biosourcés sont des plastiques dont les matières premières sont entièrement ou en partie renouvelables, c’est-à-dire non pétrochimiques. Elles peuvent être végétales, animales, résiduelles ou encore algales. Néanmoins, la part de matières renouvelables dans les plastiques biosourcés n’est à ce jour réglementée par aucun texte : ces derniers peuvent ainsi être composés en partie de plastique conventionnel. Ils ne sont pas systématiquement biodégradables, et leur recyclage est difficile à mettre en œuvre car ils sont difficiles à différencier des autres plastiques dès lors que l’on tente de les trier : ils sont donc en majorité enfouis ou incinérés. Enfin, leur bilan environnemental est mal connu, car leurs propriétés méthanogènes, leur recyclabilité comme leur caractère biodégradable ou non restent à déterminer. En résumé, c’est une filière opaque, dont les coûts de production et de retraitement sont encore trop élevés pour en faire une alternative intéressante, sans compter que sa dimension « green » fait débat.

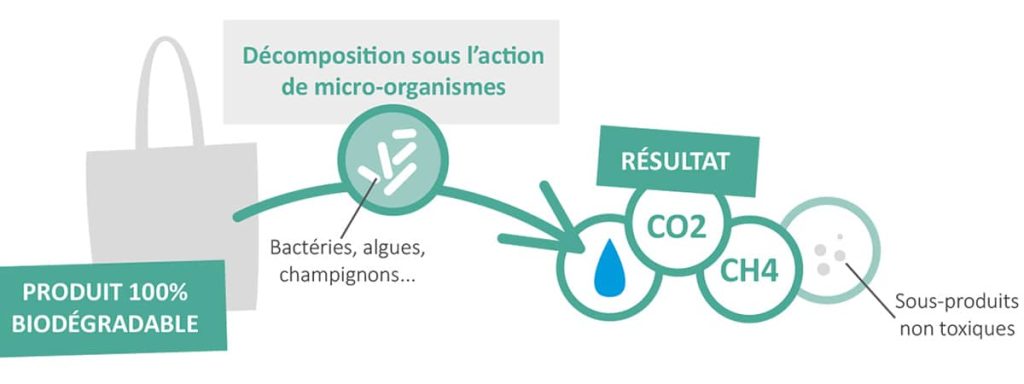

Quant aux plastiques biodégradables, même s’ils présentent des avantages, leur filière est encore loin d’être parfaitement structurée, et contrairement à ce que le terme « biodégradable » pourrait laisser penser, leur impact environnemental n’est pas nul. Pour mémoire, un matériau est dit biodégradable « s’il peut être décomposé sous l’action de micro-organismes (bactéries, champignons, algues…). Le résultat est la formation d’eau, de CO2 et/ou de méthane et éventuellement de sous-produits (résidus, nouvelle biomasse) non toxiques pour l’environnement », nous dit l’Ademe.

Les plastiques biodégradables sont donc composés de polymères qui se décomposent sans nuire à l’environnement, que ces polymères soient d’origine naturelle ou pétrochimique. Néanmoins, ces plastiques sont également composés d’additifs et d’ingrédients plastifiants dont les effets de long-terme sur l’environnement sont particulièrement douteux. Par ailleurs, leur mode de dégradation est souvent long et complexe à mettre en œuvre techniquement, à condition évidemment qu’ils soient collectés et triés au préalable, ce qui est une difficulté supplémentaire.

Enfin, ces deux catégories de bioplastiques ne doivent pas être confondus avec les plastiques oxo-dégradables ou oxo-fragmentables, qui ne sont ni composés d’ingrédients naturels ou recyclés ni biodégradables, mais se délitent plus rapidement en particules tout aussi nocives que les plastiques ordinaires.

Le plastique, que ce soit sous ses formes les mieux connues ou dans le cadre de ses derniers développements technologiques, fait donc figure de vilain petit canard en matière d’éco-responsabilité : ses effets sont mal connus, son recyclage est limité, et la complexité de sa composition rend difficile une juste communication à l’égard des consommateurs. Par ailleurs, même dans le cadre d’un recyclage efficace, il est nécessaire de mêler au vieux plastique du plastique neuf pour obtenir des produits de qualité. L’utilisation même raisonnée du plastique ne peut donc mener qu’à l’augmentation de la présence de ce matériau dans les écosystèmes, avec les conséquences néfastes que l’on sait.

Splendeur et misères de la filière du papier

Après l’interdiction de la mise à disposition de sacs en plastique dans les commerces français en 2017, de nombreux supermarchés se sont donc tournés vers le sac en papier, aussi bien pour transporter fruits et légumes en vrac que le reste des courses. Le papier, issu de fibres naturelles et biodégradables, peut paraître une alternative durable au plastique. C’est néanmoins méconnaître les différentes étapes de transformation des fibres pour obtenir un papier lisse, homogène et prêt à l’emploi : l’industrie du papier a en effet également une face sombre.

Les fibres qui constituent la matière première du papier subissent de nombreuses opérations de transformation, depuis leur broyage jusqu’à la découpe du papier en feuilles de format standardisé. Les processus de production industrielle du papier consomment donc énormément d’énergie, mais également de ressources précieuses. En effet certaines de ces opérations, très gourmandes en eau, ont pour conséquence le rejet de solutions résiduaires qui doivent par la suite être épurées. Il s’agit notamment de :

- La mise en pâte. Lorsqu’il s’agit de papier recyclé, les fibres de carton et de papier utilisées comme matière première sont mises en suspension dans l’eau afin d’être reconditionnées en pâte de papier. Elles subissent également, à cette étape de la production, un désencrage par ajout dans l’eau de solvants. À noter enfin que les encres elles-mêmes sont souvent très polluantes, et que certains déchets comme les agrafes, rubans ou couvertures plastiques se retrouvent alors dans les eaux à traiter. Dans le cas de la pâte de bois, les fibres de cellulose sont séparées les unes les autres sous l’action de produits chimiques très nocifs mélangés à de l’eau ou propulsés par de la vapeur: il peut s’agir de soude caustique, de sulfates, ou encore de bisulfites.

- Du blanchiment, première source de pollution dans le processus de production du papier. Selon le type de papier produit, on procède ensuite au blanchiment de la pâte de papier, par ajout d’autres produits chimiques qui délient les derniers adhésifs naturels présents dans les fibres : ce sont essentiellement des composés du chlore. Là encore, de grandes quantités d’eaux résiduaires sont rejetées.

- Des techniques de séchage du papier. Elles ont pour conséquence le rejet sous forme de liquide ou de vapeur de l’eau contenue dans la pâte de papier, qui a été au cours des étapes précédentes chargée en ingrédients nocifs divers. De plus, cette étape représente une consommation d’énergie phénoménale. À titre de comparaison, la fabrication d’une tonne de papier nécessite l’équivalent de la consommation annuelle moyenne d’un ménage français en électricité.

- Enfin, d’autres opérations comme la préparation du bois, la cuisson de la pâte et autres lavages et vidanges contaminent également l’eau utilisée.

Les eaux résiduaires de l’industrie du papier comptent ainsi parmi les plus polluants et les plus dangereux des effluents industriels. Elles ont pour caractéristiques la présence importante de polluants non solubles et indécantables, la présence de polluants solubles mais réfractaires aux procédés organiques de dégradation, et enfin un rythme de production effréné. Le blanchiment à lui seul représente par exemple de 20 à 40 mᶟ d’eau usée par tonne de pâte.

Pour tenter de limiter l’impact environnemental de ce secteur, de nouvelles techniques de blanchiment ont été mises au point, sous les labels ECF (Elemental Chlorine Free) et TCF (Totally Chlorine Free). Si la mention TCF indique que le papier a été traité sans utilisation de chlore ou de dérivés chloriques, en revanche la mention ECF n’indique qu’une légère amélioration par rapport aux procédés classiques. L’idéal est donc de se procurer du papier non blanchi… ce qui ne résout pas pour autant les problématiques liées aux autres étapes de production.

Notons enfin que le sac en papier, en dépit de ses avantages apparents, fait l’objet d’un taux de réutilisation moins important : on ne voit jamais un consommateur revenir en magasin avec le sac kraft qui lui servi à transporter ses légumes quelques jours auparavant. Vulnérable à l’humidité, moins solide que le plastique et souvent composé aussi d’autres matériaux moins aisément recyclables, le papier n’est pas suffisamment écologique ou pratique pour constituer une alternative durable au sac plastique.

Le sac écologique : un sac qui protège l’environnement

Consciente des enjeux environnementaux et de la nécessité d’un développement durable, la société française « Les Mouettes Vertes » crée et fabrique de façon engagée des sacs écologiques personnalisables depuis plus de 15 ans. Ces sacs tissés, disponibles en plusieurs coloris, sont utilisés par de nombreuses sociétés car ils permettent de créer un lien durable avec leur cible commerciale, notamment lors d’un évènement d’entreprise.

Durables, ces sacs écologiques colorés sont à intégrer à votre stratégie de communication car ils renforcent votre image de marque et à diffuser vos valeurs.

Ces objets publicitaires seront les meilleurs atouts de votre entreprise et ne manqueront pas de protéger la planète.

Composés de fibres biologiques, nos modèles de sacs en coton bio sont certifiés GOTS.

Qu’ils soient proposés en jute personnalisable ou en coton personnalisable, nos sacs publicitaires écologiques remplacent à merveille les traditionnels sacs en papier kraft.

Nos modèles de grands sacs colorés peuvent contenir de nombreux objets et être utilisés comme un cabas de femme.

N’hésitez pas à faire broder votre sac shopping pour un rendu tout à fait unique.

Respectueux de l’environnement, notre gamme de sacs cabas colorés est à personnaliser au gré de vos envies.

Du côté des textiles : les différents types de sacs écologiques

La culture conventionnelle du coton

Solide, polyvalent, joli et facilement recyclable, le cabas en coton apparaît comme un candidat sérieux au remplacement des sacs plastiques. Première fibre textile naturelle utilisée au monde, le coton représente une vaste filière industrielle et agricole, répartie essentiellement aux États-Unis et en Asie, notamment en Inde, en Chine, en Ouzbékistan et au Pakistan ; on trouve par ailleurs des exploitations de coton en Turquie, au Brésil, ou encore en Australie. Mais toutes ces exploitations se valent-elles ? Produisent-elles des fibres de qualité homogène, et surtout quel est l’impact de leurs méthodes de production sur l’environnement et la santé humaine ? Nous verrons que le cabas en coton, qui a pour lui sa qualité naturelle et son fort taux de réutilisation, n’est pas toujours une solution durable.

La culture intensive du coton, notamment dans des milieux où le climat n’est pas spécifiquement adapté aux besoins en eau des plants, nécessite la mise en œuvre d’une politique d’irrigation très importante et un apport constant en semences. En effet, quoi que le coton soit une espèce durable, elle est généralement semée et plantée chaque année, sur le modèle des cultures céréalières. Quel que soit le pays concerné, la culture conventionnelle du coton représente donc une consommation de ressources exigeante, et ce d’autant plus que les semences standardisées, moins adaptables à tel ou tel climat, nécessitent d’autant plus d’eau, d’engrais, et de pesticides.

L’ensemble du secteur du coton ne représente que 2 à 3% des terres cultivées, mais pour obtenir les rendements propres à satisfaire la demande, la culture conventionnelle du coton utilise jusqu’à 24% de la totalité des pesticides déversés sur les exploitations agricoles dans le monde. Ces pesticides, le plus souvent dispersés par voie aérienne, ont une incidence directe sur la qualité des eaux et des sols à proximité des cultures, et sont charriés à la fois par les systèmes d’irrigation agricoles et les cours d’eau naturels. Ainsi rejetés jusqu’aux embouchures des fleuves, ils menacent le fragile équilibre des zones humides et sont d’autant plus difficiles à traiter que les filtres permettant de les retenir éliminent également les micro-organismes et minéraux présents naturellement dans l’eau. Par ailleurs, le mode de dispersion des produits pesticides entraîne une diffusion parfois majoritaire de ces derniers dans l’atmosphère. Ils peuvent ainsi retomber par l’intermédiaire de la pluie après avoir parcouru de très longues distances, ce qui rend leur nocivité d’autant plus menaçante.

Si les effets aigus des pesticides sur la santé, et notamment auprès des cultivateurs de coton, sont relativement bien connus (réactions allergiques ou inflammatoires, affections cardio-respiratoires, etc.), en revanche les conséquences à long-terme de l’exposition du corps humains aux pesticides sont encore floues et difficiles à étudier. Un nombre croissant d’études scientifiques s’attachent néanmoins à décrire et quantifier ces conséquences, avec comme principales conclusions le rôle prépondérant des pesticides dans l’apparition de cancers, notamment de leucémies et de lymphomes, d’infirmités à la naissance, de troubles de la reproduction, d’effets neurotoxiques et d’effets perturbateurs endocriniens. Dans la région du Penjab, où pousse la majeure partie du coton indien, de nombreux agriculteurs souffrent ainsi d’affections dont les pesticides sont une cause non négligeable, la presse étant allée jusqu’à parler de « cancer belt » pour désigner cette portion très cultivée du territoire indien.

Notons enfin que la nécessité de laver les fibres imbibées de pesticides conduit au rejet d’eaux résiduaires et contribue à faire doubler la consommation d’eau normalement nécessaire pour la production du coton. On trouve également, dans ces résidus, tous les produits servant à blanchir ou teindre le textile, avec comme conséquence la dévastation parfois irrémédiable des écosystèmes à proximité des usines, et l’appauvrissement progressif des terres cultivables. Le seul avantage réel du cabas en coton non bio serait donc lié à ses possibilités de réutilisation, sous sa forme originelle ou par le biais du recyclage des fibres.

L’essor des exploitations de coton biologique

Néanmoins, l’impact écologique et sanitaire du coton conventionnel étant de mieux en mieux connu, fabricants et cultivateurs se tournent de plus en plus vers des fibres biologiques, répondant non seulement aux enjeux de préservation de la matière première par le biais de la fertilité des zones cultivées, mais également à une demande croissante de traçabilité de la filière exprimée par les consommateurs finaux.

Le coton biologique, plus résistant et plus respectueux de l’environnement comme de la santé des cultivateurs et des consommateurs, retiendra donc notre faveur par rapport au plastique, au papier, ou encore au coton non bio. La jeunesse de cette filière et l’attention portée à la qualité des produits finis pourra, il est vrai, faire de l’achat d’un cabas en coton bio coloré un investissement plus important. Néanmoins, cette dépense est très rapidement rentabilisée et se justifie aussi par les possibilités qui se développent en matière de style, de couleurs et de design. Surtout en cette période faste ou le tote bag est à la dernière mode !

Pour mieux évaluer la fiabilité des différentes certifications du coton bio, vous pouvez également vous référer à notre dossier sur les labels utilisés par l’industrie textile, afin de vous assurer de la réalité de l’engagement social et environnemental de vos fournisseurs.

Les autres alternatives textiles biologiques

La spécificité du climat sous lequel le coton pousse de manière optimale, la nécessité de diversifier les types de textile utilisés pour répondre aux demandes des clients ainsi que l’essor du « made in France » poussent également les entreprises à se tourner vers d’autres fibres textiles, dont les filières biologiques sont encore en phase de développement mais dont les perspectives d’avenir sont prometteuses.

Le lin biologique

Le lin, dont la culture exige une grande maîtrise technique et s’effectue sur des rotations assez longues (tous les 6 à 7 ans), gagne peu à peu ses lettres de noblesse dans l’industrie textile moderne. Il a l’avantage de très bien préparer le sol pour d’autres cultures, de n’exiger que de faibles quantités d’eau et d’avoir un bilan carbone absolument positif. Cultivé essentiellement en France, en Belgique et aux Pays-Bas, il permet par ailleurs la constitution de filières locales de production textile – du moins en théorie, compte tenu de la prépondérance de la Chine dans les opérations de tissage et de teinture des fibres : c’est en effet en Chine qu’ont été délocalisés la plupart des peigneurs, filateurs, tisseurs et tricoteurs du lin. 70% des exportations en direction de la Chine sont originaires de France : il y a donc encore du progrès à faire de ce point de vue ! De plus, le lin possède des propriétés thermorégulatrices, absorbantes et anti-allergiques connues depuis l’Antiquité, et s’avère aussi résistant et durable que le coton, ce qui en fait un matériau de choix pour fabriquer des vêtements ou des cabas.

Néanmoins, les cultivateurs de lin s’accordent à dire que cette culture est plus risquée et plus difficile à réaliser que celle du coton, dans la mesure où la longueur des cycles de rotation, la technicité des opérations de mise à nu de la fibre (le teillage) et enfin la complexité des moyens de lutte contre certains parasites entraînent de nombreuses incertitudes quant au rendement des exploitations. C’est pourquoi le lin est en moyenne plus cher que les autres fibres textiles bio, et ne constitue qu’une solution marginale dès lors qu’il s’agit d’atteindre des volumes de production équivalents aux autres types de fibre. Notons enfin que les tissus en lin, aisément froissables, subissent souvent des traitements chimiques de finition, dont l’impact écologique est pour sa part non nul !

Les fibres de bambou

Considéré comme une fibre écologique, le bambou est depuis une quinzaine d’années en plein essor. Contrairement à ce que l’on pourrait penser, le bambou est très rarement vendu sous sa forme de fibre naturelle. En effet, la fibre naturelle étant très rêche en l’état, 99% des textiles en bambou sont aujourd’hui fabriqués à partir de viscose.

De nombreuses entreprises capitalisent sur l’attrait du bambou auprès des consommateurs et mettent en avant le caractère innovant et écologique des textiles ainsi conçus.

La culture du bambou est respectueuse de l’environnement. Le bambou pousse très vite, sans nécessiter l’ajout d’eau, d’engrais ou de pesticides, et constitue un facteur de développement très important pour les pays producteurs, notamment au Nigéria et en Éthiopie.

Les racines du bambou réduisent l’érosion des sols, les préservent et permettent leur régénération.

Une forêt de bambou est capable d’absorber 35% de CO2 de plus qu’une forêt d’arbres feuillus.

L’usage du bambou est très apprécié par l’industrie du textile.

Le bambou est très souvent utilisé pour la confection de vêtements de sport, de pyjamas, de sous-vêtements ou encore dans nos culottes menstruelles. On confère au tissu de bambou de multiples propriétés telles que la légèreté, son pouvoir respirant, sa douceur et son aspect naturellement antibactérien.

De plus, l’entretien des produits composés de bambou est très facile.

Seul bémol : la transformation de la plante de bambou en fibres repose sur un processus lourd et polluant incluant l’utilisation de produits chimiques.

Le lyocell

Commercialisé essentiellement par l’entreprise autrichienne Lenzing sous le nom de Tencel, le lyocell est un textile fabriqué à partir de pulpe de bois, entièrement biodégradable et recyclable. Les matières premières utilisées peuvent être le bambou, l’eucalyptus ou encore le hêtre, mais le lyocell en lui-même n’est pas une fibre naturelle : en effet, la pulpe de bois est transformée en fibre textile grâce à un solvant organique recyclable et non-toxique, le NNMO (monohydrate de N-oxyde de N-méthylmorpholine).

Développé dans les années 1970, le lyocell est aujourd’hui surtout utilisé en remplacement de la viscose, dont il imite la douceur et la fluidité sans en avoir les inconvénients en matière d’impact environnemental. En effet, dans le cas de la viscose, la cellulose naturelle est traitée au moyen de produits très polluants, alors que pour la fabrication du lyocell le solvant utilisé n’est pas nocif, et est de toute façon récupéré de manière quasi intégrale pour être ensuite réutilisé. De plus, il serait possible d’en faire une filière plus locale, dans la mesure où les variétés de bois utilisées permettent de l’adapter aussi bien à l’Europe, qu’à l’Afrique ou à l’Asie.

En matière de gestion des ressources, les forêts dont proviennent la pulpe de bois destinée à la production de lyocell sont généralement labellisées FSC (Forest Steward Council) ou PEFC (Programme de Reconnaissance des Certifications Forestières). Néanmoins, certaines cultures comme le bambou sont encore gérées de manière peu durable, ce qui doit être pris en compte. De plus, ces labels comportent, comme les labels bio, différents niveaux d’exigence : il convient donc de vérifier la part de matériaux effectivement issus de forêts durablement gérées, ou de filières de recyclage.

Notons par ailleurs que le procédé de transformation de la pulpe en fibre requiert énormément d’énergie, et que la qualité biodégradable du lyocell a également un impact sur la durabilité des vêtements ou cabas façonnés dans cette matière : la fibre est en effet sensible à l’eau, a tendance à se froisser et à fibriller lorsqu’elle est mouillée, et en l’état actuel des processus de production, le traitement de ces légers défauts nécessiterait l’ajout de produits de finition plus nocifs.

Le chanvre et le jute reviennent à la charge

Considérés comme peu nobles en raison de leur historique de fabrication de sacs agricoles, le chanvre et le jute ont été mis de côté par l’industrie du vêtement et de l’accessoire pendant de nombreuses années. Néanmoins, leur résistance et leur prédisposition pour la culture biologique les ont remis en vogue, et ils sont désormais employés dans la fabrication non seulement de sacs et de tissus d’ameublement, mais également d’accessoires et de vêtements. Cultivés dans le cadre d’une rotation raisonnée des cultures, le jute comme le chanvre contribuent à la régénération des sols et à la meilleure santé des espèces cultivées avant ou après eux.

Le chanvre est une plante annuelle, très résistante à l’eau (y compris pendant les moussons), et qui connaît peu de parasites ou de maladies. Si ses fibres sont transformées en textile au terme de plusieurs opérations de rouissage (séparation naturelle des fibres sous l’effet d’un champignon), de filage puis de tissage, les autres parties de la plante sont également exploitables, ce qui en fait une culture extrêmement rentable : les graines, une fois récoltées, servent en effet à produire de l’huile, tandis que la chèvenotte (la partie des fibres qui reste soudée au terme du rouissage) constitue un excellent matériau isolant. De plus, la période de rotation du chanvre est plus courte que celle du lin (3 ans contre 6 ou 7), et les deux plantes ont les mêmes vertus antibactériennes. Notons enfin que le climat français lui convient parfaitement, ce qui laisse entrevoir des possibilités d’offre totalement « made in France ».

Le jute est la deuxième fibre naturelle la plus produite au monde, après le coton. Sa culture, très exigeante en main d’œuvre, nécessite peu d’engrais et de pesticides : c’est donc une espèce de choix pour les exploitations biologiques Les étapes de transformation sont les mêmes que pour le chanvre, avec une phase de récolte, de rouissage, puis de traitement des fibres pour en faire du textile. Néanmoins, le jute ne pousse que sous des climats tropicaux ou très humides, et à ce jour l’Inde, le Bangladesh et le Népal en sont donc les principaux producteurs, et le cultivent souvent en rotation avec le riz. Totalement biodégradable et recyclable, la fibre de jute est appréciable par sa longueur, sa résistance et son effet brillant, ainsi que ses propriétés antistatiques et isolantes. Notons enfin que c’est une fibre très respirable, et donc agréable à porter. Quant au reste de la plante, on peut en user comme isolant, comme combustible ou encore la réduire en extraits entrant dans la composition de certains cosmétiques. Est-ce la solution parfaite pour autant ? Pas forcément, car en raison de la mollesse de ses fibres, le jute est souvent associé à un pelliculage plastique pour créer des sacs avec un minimum de tenue. Gare donc à la composition des cabas fabriqués avec cette matière.

Conclusion : le sac écologique, un sac pratique et durable !

Chez Les Mouettes Vertes, le choix de se tourner vers un coton biologique de très haute qualité, durable et facilement recyclable, a été motivé par notre désir de proposer une alternative écologique et naturelle au plastique, tout en nous amusant avec les formes et les couleurs, pour vous proposer des sacs et accessoires qui allient éthique et style.

Si le textile, qu’il soit coton, chanvre, lin ou lyocell, paraît le meilleur candidat au remplacement du plastique et du papier, il est à noter que tous les textiles ne se valent pas et que la culture conventionnelle des plantes à fibre a un impact environnemental très lourd. Faire le choix du textile, c’est donc aussi se tourner vers des fibres biologiques, et vers des entreprises dont la politique en matière d’engagement social permet une plus juste répartition de la valeur créée.

Les Mouettes Vertes se sont donc tournées vers l’Inde pour trouver des fibres de coton bio cultivées et transformées dans le respect de tous les acteurs de cette filière. L’Inde a en effet l’avantage d’avoir un secteur du coton parfaitement structuré, transparent, et traçable. De plus, nous avions à cœur de préserver l’emploi là où il est le plus précaire : c’est pourquoi notre atelier de confection près de Mumbai prête la plus grande attention au bien-être de ses salariés, et les rémunère de manière digne, de manière à faire grandir l’économie locale. Enfin, leur maîtrise et leur savoir-faire ancestraux nous permettent de proposer des produits dont les finitions et coloris sont impeccables !

Convaincus ? Si c’est le cas, n’hésitez pas à faire un tour du côté de nos sacs et cabas personnalisés et colorés pour mettre en pratique vos bonnes résolutions !